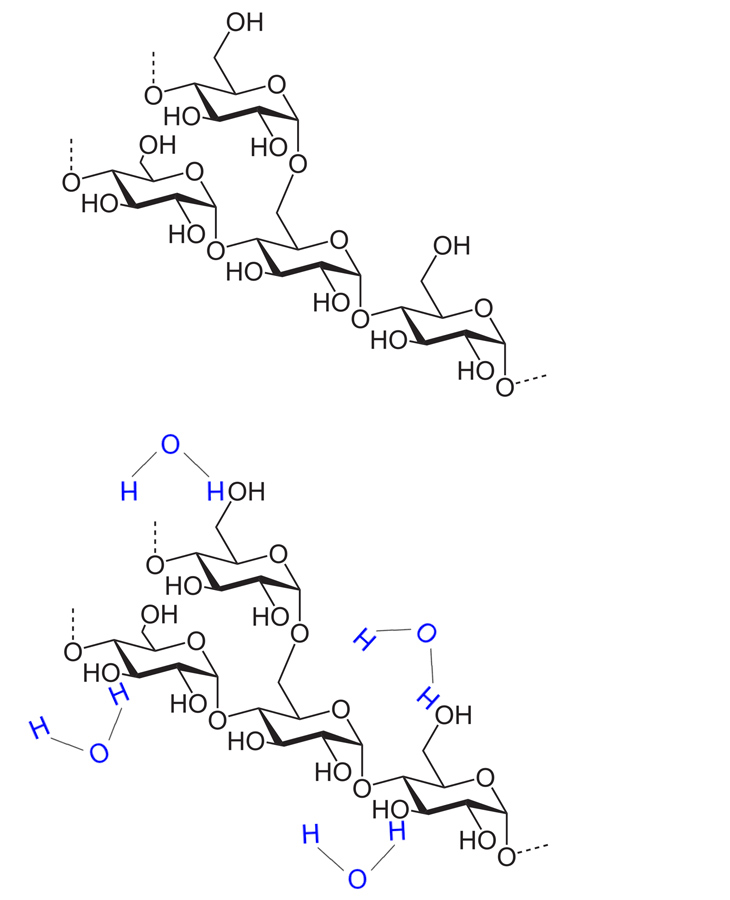

We found most of the food gels belong to hygromorphic materials, which can hydrate and change volume when absorbing water through hydrophilic interaction within their molecular or inter- molecular structure. Starch is an example of a hydrophilic polymer, since it has -OH groups present on its surface. One way to quantify a material’s ability to hydrate is to use the swelling index.

- All / Materials / Interfaces / Tools

Desining Substract Film

We fabricate substrate film that has heterogeneous density distribution, which can cause differntial expansion upon hydration. We found that, when preparing film in a petri dish and evaporating water only from the top of the film, the desired film heterogeneity was achieved. The solid-air boundary contains a higher con- centration of material due to migration and aggregation of the solids upon drying. After forming a dried top layer, water evaporation in the lower portion of the film is slowed. This results in the formation of a dense top layer, as well as a loose, porous bottom layer, of gelatin films.

Adding Shape Constraints

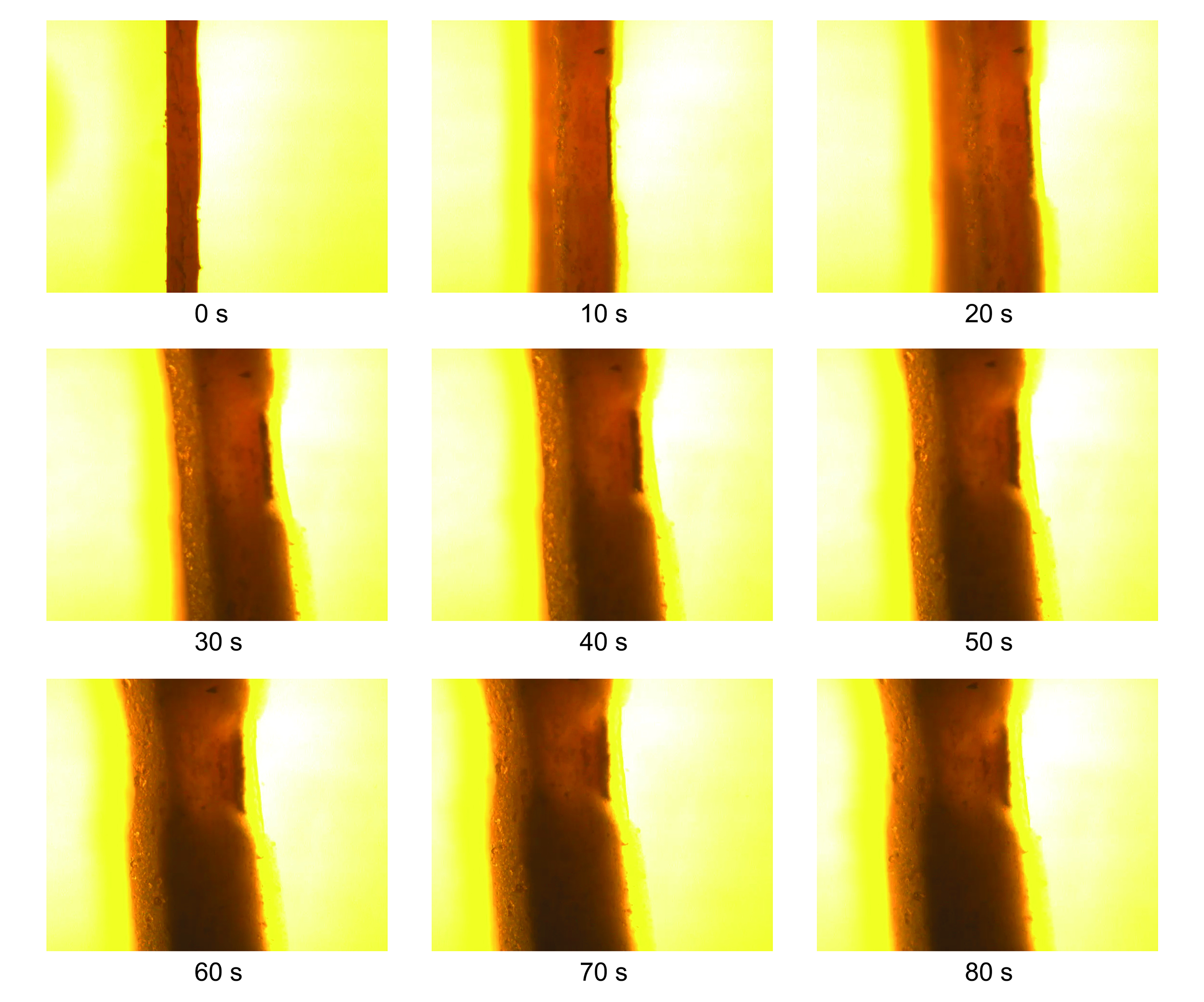

In order to achieve controllable bending behavior, an ethyl cellulose strip is introduced as both a shape constraint and a water barrier on top of the film. This semi-rigid strip structure could help regulate the binding direction and create dynamic shape changing by modulating the top surface’s water adsorption rate (majorly due to the decreased water adsorption area).