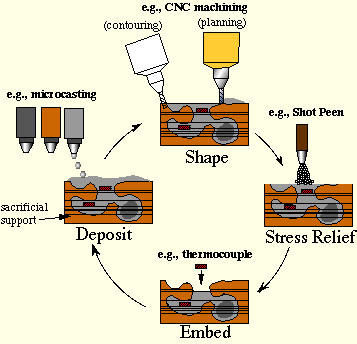

Shape Deposition Manufacturing (SDM) is a solid freeform fabrication (SFF) process being developed at Carnegie Mellon and Stanford University to build complex structures which could not be built with any conventional fabrication process.

SFF methodologies are based upon material additive

processes to incrementally build-up cross-sectional layers of arbitrarily

complex shapes. SFF has been widely investigated as a way to rapidly and

automatically fabricate parts directly from CAD models for such applications

as rapid prototyping and customized low-batch production. Current SFF processes,

however, have not taken advantage of the potential benefits of incremental

deposition techniques to build heterogeneous structures,

i.e., multi-material, functionally-grade, embedded structures. SDM

is being developed to build such heterogeneous structures made of metal,

plastic and ceramic materials.

SDM integrates material additive with material removal processes, as well

as other intermediate processing operations, such as embedding and stress

relief, which operate on each layer. Individual layer segments are deposited

as near-net shapes and then accurately machined to net-shape before depositing

additional material. Each layer also consists of sacrificial support material

which is removed when the entire part is completed. Several types of deposition

processes are being investigated including weld-based processes, UV curables,

gel-casting, and 2-part epoxy mixtures. For one example, 'micocasting' is

novel process which deposits discrete droplets of super-heated metals such

as stainless-steels with copper sacrificial supports.

Next-generation production tooling

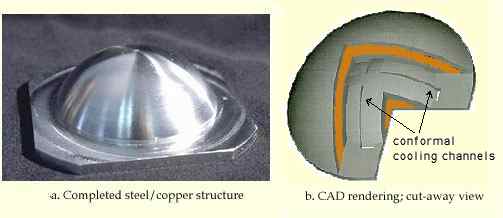

Next generation production tooling are dies for injection moling with a strong steel exterior, an internal copper core for thermal conductivity and conformal cooling channels. A conceptual example shown below is a copper-steel structure with complex three dimensional cooling channels.

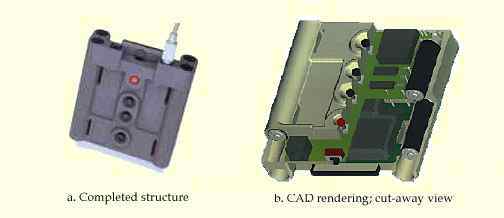

Specialized wearable computers

are custom made computers that a person can wear on his/her body. The example

shown below is a embedded computer which displays schematics for maintenance

operations. The computer is embedded in rugged polyurethane structure,

shaped to conform to the human operator.