How does the process work and how a part would be built?

The Basic Process:

Building of the part:

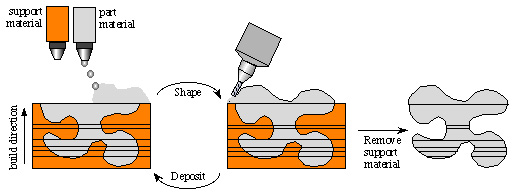

First a layer of part material or the support material that is not undercut is applied until the geometry demands otherwise. Undercut is when two types of material occupy the same horizontal position and different vertical positions at the same time. So the bottom layer must be applied first. Obviously the application order is paramount. Obviously the application order is paramount. The graphic below demonstrates the order of deposition in a several layers of one part.

The thickness of each layer and the sequence for depositing and shaping the primary and support materials in each layer will vary based upon part geometry. For layers in the first category (e.g., layer in Figure b), the primary material is deposited first and then machined. The support material is then deposited then the entire layer surface is planed. For layers in the second category (e.g., layer in Figure c), the support material is deposited and machined first; then the cavity created by the support structure forms the undercut features of the part. Layers in the third category containing both types of surfaces must be further decomposed into layer segments, or 'compacts', which are deposited and shaped in a sequence such that all under-cut features (of either the primary or support materials) are formed by the previously shaped non-undercut feature (e.g., layer in Figure b).

After a small section hardens, the material is machined using a CNC milling machine until the milled surface is exact. So, when the adjoining layer is added, the surfaces will be precisely as the designer wanted and will not require machining after the part is complete.

The cleaning station is used to remove cutting oil from the part that builds up during the cutting process, before additional deposition takes place.

The cycle will repeat until all the parts and supports are constructed layer by layer. In addition to the rapid prototyping of complex shapes, selective additive material processing enables the fabrication of multi-material structures and it also permits prefabricated components to be embedded within the growing shapes. This can be such components as electronics and microchips.

When this layering process is complete, the supports are melt away from the part. Because of the difference in melting points of the part and support, this is plausible.