Shape Deposition Manufacturing

Jay McCormack

Gioel Molinari

Alan Tomko

SDM is an advanced rapid prototyping technique that can be used to make parts from various metals, plastics, resigns , and ceramics. The technique is time consuming and not-so-rapid, but the parts are extremely acurate, can serve as real working parts, and can be made from a variety of different materials.

The process includes several steps:

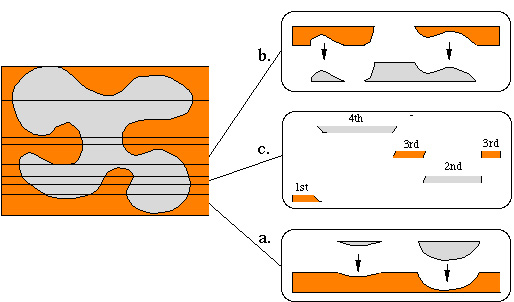

First a layer of part material or the support material that is not undercut is applied until the geometery demands otherwise. Undercut is when two types of material occupy the same horizintal position and different verticle positions at the same time. So the bottom layer must be applied first. Obviously the application order is paramount. The graphic below demonstrates the order of deposition in a several layers of one part.

After a small section hardens, the material is machined using a CNC milling machine until the milled surface is exact. So, when the adjoining layer is added, the surfaces will be precisely as the designer wanted and will not require machining after the part is complete.

5

axis CNC milling machine

5

axis CNC milling machine

The cleaning station is used to remove cutting oil from the part that builds up during the cutting process, before additional deposition takes place.

Part

Washer

Part

Washer

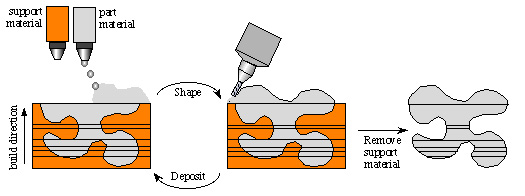

This cycle continues until the part and support are constructed layer by layer. Components can be embeded in the part at any time by mannually adding the component before a layering process. The layer will then hold the component in place. This allows for some interesting applicationssuch as embeded electronics. The grtaphic below gives an overview of the entire process and shows and embeded component.

When this is complete, the support material is removed by melting. This is possible due to the difference in melting points of the part and the support.

To learn more about Shape Deposition visit these guys..........

Carnegie Mellon Shape Deposition Lab

The Rapid Prototyping Lab at Stanford

and check out our slides from our presentation on 2/19/98.

Jay McCormack <jmeq@andrew.cmu.edu>