The SDM Laboratory

There are two SDM testbed laboratories, inlcuding one at Carnegie Mellon University and the other at Stanford University.

These facilities include both flexible robotic manufacturing systems as well as dedicated CNC

shaping/deposition machines. The SDM Laboratory at CMU is described below.

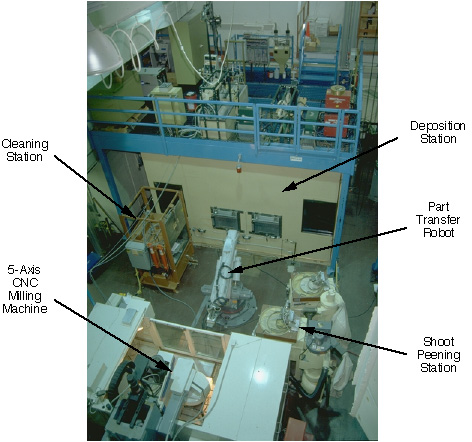

In order to be able to quickly explore alternative processes for SDM, we have implemented a robotic SDM system (see figure above). With this approach, parts are built-up on pallets, which are transferred from station-to station using a robotic palletizing system. Each station has a pallet receiver mechanism. The part transfer robot places the pallet on the receiver, which locates and clamps the pallet in place. The current SDM robotic facility consists of four processing stations; CNC milling, deposition, shot-peening and cleaning. The deposition station also uses robotics to integrate multiple deposition processes. Embedding operations are currently done manually. The entire SDM system is coordinated by a customized controller provided by Yokogawa Electric Corporation.In the testbed facility, the part transfer robot is a 6-DOF Motoman robot with a 120 kg payload capacity. The pallets have a 12" X 12" footprint. The shaping station is a 5-axis FADAL VMC-6030 CNC milling machine with a 21-head tool changer mechanism. The hydraulically-actuated receiver used in this station is able to repeatedly locate the pallet within approximately 0.0002 inches. When cutting fluids are used in milling operations, the pallet is then transferred to a cleaning station to remove residuals. A shot peening station, which uses a conventional pressurized media delivery system to blast small pellets of metal against layers, can be used to redistribute the stresses in a deposited layer.

Deposition Station

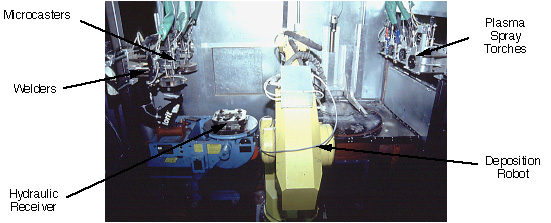

The deposition station consists of an acoustic chamber (for noise abatement and dust containment), an air handling system (for dust filtration and collection) and a robotic deposition system. The deposition robot, which is a 6-DOF GMF-S700 system, is equipped with a tool-changing wrist and is able to acquire one of several different deposition sources, which are mounted to a docking mechanism. To deposit each material, the robot picks up the appropriate deposition head and manipulates it over the growing shape. The feedstock mechanisms and power supplies for these sources are located upon a mezzanine above the acoustic chamber, and the pallet is moved into the chamber through a trap door. The current sources include arc and plasma sprayers, MIG welding, 'microcasting' and a hot wax gun. The wax is used as complementary support material for building polyurethane (PU) structures.

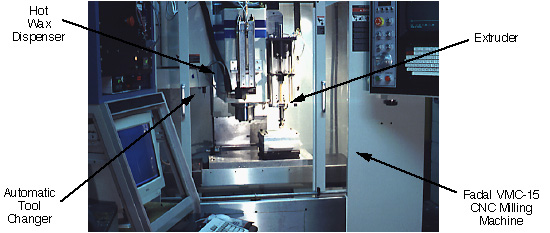

Commercialized SFF systems are customized machines, and high performance SFF apparatus can be relatively expensive. As an alternative to customization, or to robotic automation, we are exploring implementing SDM by simply adding deposition apparatus directly to existing CNC milling machines such as are typically found in machine shops throughout the world. In addition to shaping operations, the CNC milling machine provides the precision motion control required for deposition. When not being used for SDM, such an integrated CNC deposition and shaping machine can still be used as a conventional milling machine. For one example, the integrated CNC deposition/shaping machine shown above is being used to investigate the fabrication of 'green' ceramic structures using an extrusion deposition process. The machine is based upon a commercially available Fadal VMC-15 mill with an automatic tool changing carousel. An high pressure extruder is mounted on a pneumatically actuated slide that is attached to the Z-axis spindle housing of the NC machine. The slide is retracted when the extruder it is not in uses (e.g., during machining operations) and lowers the extruder into the workspace during deposition operations. The extruder is used to deposit both support and part materials; currently, we manually switch extrusion tubes/nozzles preloaded with the different materials.