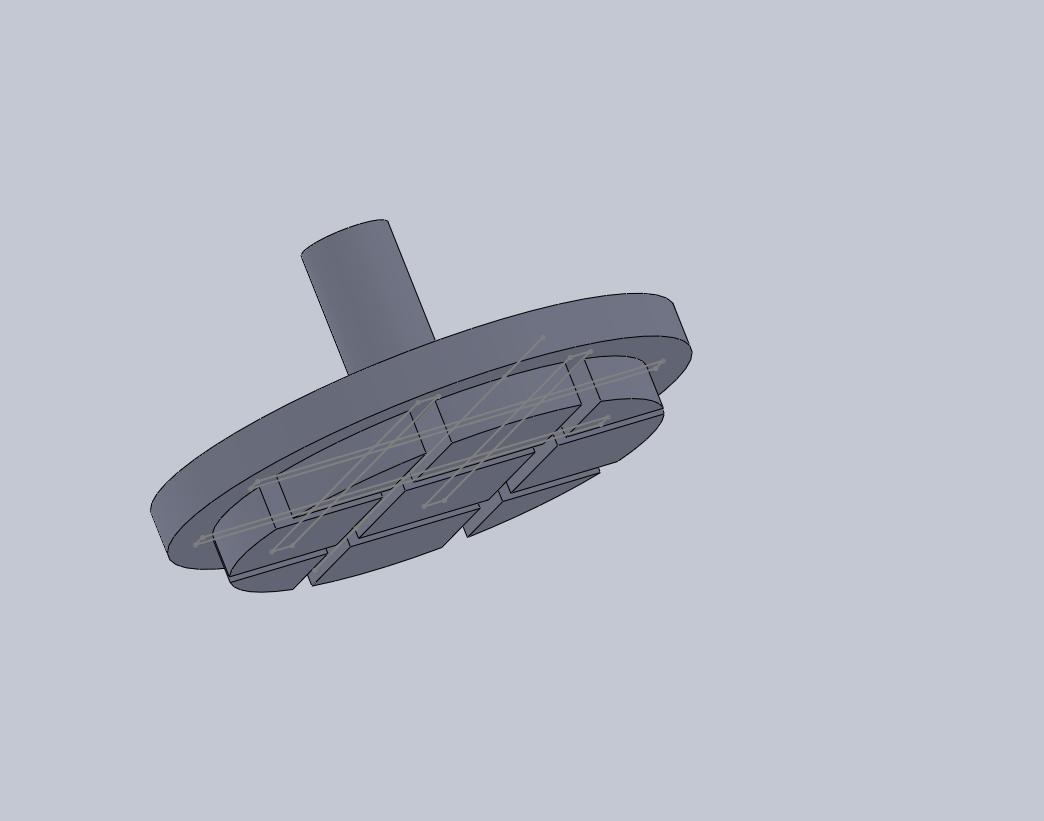

Our toy is called the "How Will You Tilt-O-Top." After deciding on a toy concept we began our steps of manufacturing. The first step was to sketch what we wanted our final design to look like. We came up with a concept we wanted to pursue and from there we needed to translate the sketch into a solid works file. This took a little bit more figuring out than we thought initially. This was because our group was not very familiar with solid works so the model was difficult to construct at first. Once we completed our model we saved it in .stl format so that the machine could read our 3-D file. We then needed to decide how exactly we were going to machine our toy. We first considered CNC (Computer Numerical Control)milling machines however they can't do undercuts usually, especially ones as severe as we have on our top. This would mean we'd have to fixture each part twice, which is difficult. Laminating laser cut pieces would work, except for the bottom of the top, which has to be rounded, not a flat approximation. For these reasons we decided on FDM printing (Fused Deposition Modeling). We used ABS plastic (Acrylonitrile Butadiene Styrene) for the toy and its lid because it would be relatively light weight and was also relatively inexpensive in comparison with other options. As for the weights that can be put inside the top to adjust the way it rotates they are made of steel. We bought ten of each; 1/8in. square by 3/4in., 1in., and 1-1/4in. respectively. We were going to use the machine in Larry's shop to constuct our toy however right before we had a chance to submit our file it broke. Ethan spoke with Larry about troubleshooting the 3-D printer. The issue was that the nozzle that prints the filler material was not working. We figured this was either due to poor heat conduction, or something obstructing the aperture. When we came in Larry said he had cleaned the nozzle a few times, so there wasn't much more to do about the conduction possibility. He then tried to use a small drill bit to open up the hole, but couldn't find one that was thin and long enough. Ultimately, we tried placing it in the solvent bath, which still failed to solve the problem. The company who makes the machine will not help resolve the issue because the machine is actually a combination of parts from two machines; neither of which still offers customer service. We are in the cue for the Architecture machine that is currently down. Once one of the machines is fixed we hope to finally complete our toy top!

PROJECT 2

Carnegie Mellon University

March 4th, 2010