Classifying Raw Materials with Discriminative Illumination |

| |

Classifying raw, unpainted materials --- metal, plastic, ceramic,

fabric, etc. --- is an important yet challenging task for computer

vision. Previous works measure subsets of surface spectral

reflectance as features for classification. However, acquiring the

full surface reflectance is time-consuming and error-prone. In this

project, we propose to use coded illumination to directly measure

discriminative features for material classification. Optimal

illumination patterns---which we call ``discriminative

illumination"---are learned from training samples, after projecting

to which, the spectral reflectance of different materials are

maximally separated. This projection is automatically realized by the

integration of incident light for surface reflection. While a single

discriminative illumination is capable of linear, two-class

classification, we show that multiple discriminative illuminations

can be used for nonlinear and multi-class classification. We also

show theoretically the proposed method has higher signal-to-noise

ratio than previous methods due to light multiplexing. Finally, we

construct a LED-based multi-spectral dome and use the discriminative

illumination method for classifying a variety of raw materials,

including metal (aluminum, alloy, steel, stainless steel, brass and

copper), plastic, ceramic, fabric and wood. Experimental results

demonstrate the effectiveness of the proposed method. |

Publications

Jinwei Gu and Chao Liu. Discrminative Illumination: Per-Pixel

Classification of Raw Materials based Optimal Projections of

Spectral BRDFs. CVPR 2012.

Jinwei Gu and Chao Liu.Supplementary

Document (with proof and other experimental details).

|

Images

|

|

A LED-based Multispectral Dome Light:

We design and build a LED-based

multi-spectral dome light for classifying

raw materials based on optimal projections of their spectral BRDFs. The

dome has 25 LED clusters. Each

LED cluster has six color LEDs which can be weighted individually

to create a desired spectrum. They are driven with Arduino boards

with PWM controls. We learn optimal illumination patterns from training samples, after

projecting to which the spectral BRDFs of different materials can be

maximally separated.

|

|

|

Database of Raw Materials:

We focus on unpainted, raw materials which are classified

based on their surface spectral BRDFs. The database includes metal,

plastic, fabric, ceramic, and wood. Within the class of metal, we

have samples of alloy (4130), aluminum (5052, 6061, 2024,

7075), steel (cold roll and hot roll), stainless steel, brass, and

copper. In total, there are 100 sample plates.

|

|

|

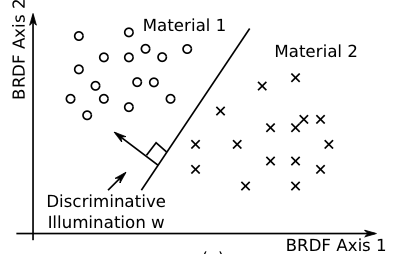

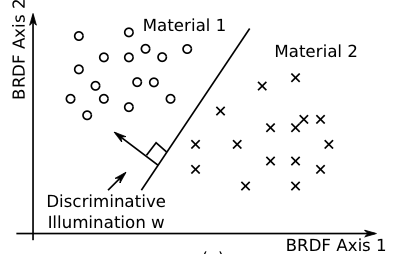

Discriminative illumination as a physically-based

linear classifier:

Our core idea is to use coded illumination as a

classifier. (a) A schematic diagram in which coded illumination

acts as a linear classifier, after projecting to which the spectral

BRDFs of different materials are maximally separated. (b) An example

of aluminum-vs-alloy classification. The image is captured by one of

the 150 LEDs of the dome which yields the best classification

performance on training data. Its classification rate on testing

data is 41\%. (c) We train a linear kernel SVM classifier from the

same training data, with the classification rate of 95% on the

testing data. The bar graph shows the learned SVM light, w, where

the 25 bar groups correspond to the 25 LED clusters and the six bars

within each group correspond to the six LEDs. The vertical axis

shows the relative brightness of each LED. Since the SVM light,

w, has negative

values, we implement it as the difference of two nonnegative

vectors. (d) and (e) show the corresponding light

patterns on the top view of the LED dome. The colors of the nodes show

the spectra of the LED clusters. (f) and (g) show the

corresponding captured images. (h) shows the difference of (f) and

(g), which is used for classification. (i) is the classification

result, shown as a binary image.

|

|

|

Extension to multi-class classification:

Multiple discriminative

illumination can be used for multi-class classification.

We show an example of fabric-vs-ceramic-vs-plastic classification

using the one-vs-all strategy. (b) The captured image under one of the 150 LEDs. (c) The learned

three SVM light vectors. (d) To handle negative values, we implement

the three SVM lights as four nonnegative light patterns. (e) shows

one of the four captured images under the SVM lights. (f) the

classification result. The classification rate is 94%. (g) In

comparison, if we only select three LEDs for classification, we can

at most have 62% classification rate.

|

|

|

From linear to nonlinear classifier using multiple

discriminative illuminations:

(a) A cascade classifier for the detection problem, which minimizes false positive

rate by adding more stages while maintaining a

small given false negative rate for each stage. (b) A toy

nonlinear example of detecting red + from blue circles. (c) Classification

results of the cascade classifier in which each stage

is a linear classifier. Top: the classification results

on the training samples. {Bottom: the classification

boundaries.

|

|

|

Aluminum detection using a cascade classifier:

We

train a four-stage cascade classifier to detect aluminum from three other

materials (ie, steel, ceramic, plastic). (a) captured image under

one of the 150 LEDs. (b)(c)(d)(e) show the learned classifier and

corresponding classification result (as a binary image) for each

stage. A linear-kernel SVM classifier is used for each stage. With

the false negative rate for each stage to be 2%, the

four-stage cascade classifier has false negative rate of 4.2% and

false positive rate of 0.07%. In comparison, if we train a

single linear light for this problem with the same false

negative rate, the false positive rate is 6%.

|

|

|

Deal with surface normal variation:

We deal with surface normal

variations by augmenting the training datasets with rotations of

BRDF vectors. This works for small variations (within +/- 10

degrees). This picture shows a simulation result. (a)(b) Renderings of two BRDFs under natural lighting. (c) A

sample with random surface normal ($\pm 10$ degrees variation in the

tilt angle, color coded). (d) The

distribution of the two BRDFs on the sample. (e) Measured image under a point light, with which it is

difficult to separate the two BRDFs. (f) Measured image under a

discriminative illumination, with which we can separate the

two BRDFs more accurately.

|

|

Video

|

|

Supplementary Video:

This video show the dome light in action. Here are several more videos:

|

|

Slides

CVPR 2012 Oral Presentation (with videos)

ICCP 2012 Poster (PDF)

|

|